how do rivets work diagram

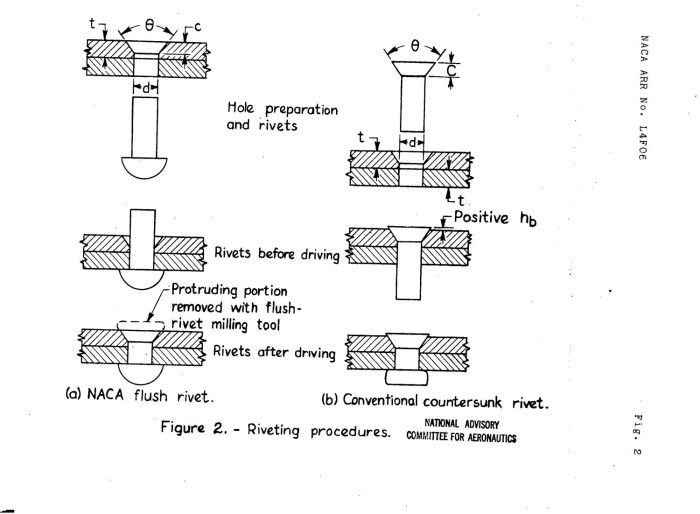

On installation the rivet is placed in a punched or drilled hole and the tail is upset or bucked so that it expands to about 15 times the original shaft diameter holding the rivet in place. Squeeze handle to pull and cut off excess mandrel and set rivet PIC 3.

Rivets and rivet set and hammer place a rivet in one end hole and place the job on a stake.

. Before using it or buying it one must have a crystal clear idea on how does a pneumatic rivet gun work. This will cause the rivet to expand. The two pieces of plastic or aluminium are drilled to a size slightly larger than the rivet.

A pop rivet is then inserted through the drilled hole and the rivet body is brought into contact. A straight metal piece is connected through the parts. Thread Anchor Rivet onto Mandrel.

The head should be pushed firmly up against the end of the gun. The quality and method of performing riveting are determined by the manufacturers professionalism and skill. Take your rivet tool and squeeze its handles together.

If two or more strokes are necessary to set rivet handle must be reopened completely. When finished the tail has the appearance of. When you do this it only take two or three taps with the rivet gun at low throttle.

Continue reading to learn how and why rivets are such an important part of the leatherworking process. Position tool with rivet by placing rivet in the hole with flange flush against surface. A open rivet b closed rivet.

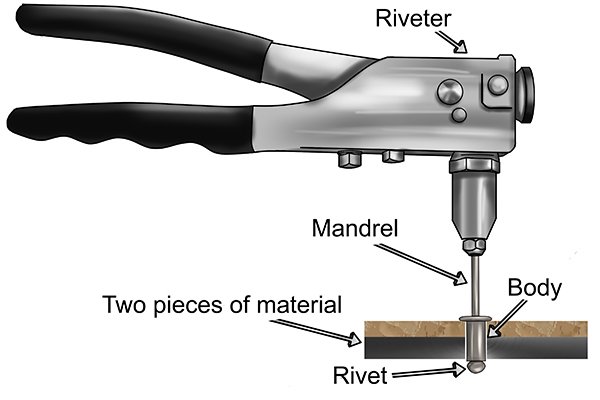

The first part is called the rivet body also known as the shell or hat and the second part is called the mandrel also known as the stem. Firmly press your rivet into the pre-drilled hole with the nub completely clearing the hole. Unscrew tool from Anchor Rivet.

Rivet as described previously proceed to rivet other end and centre of cylinder and then rivet alternately right and left of centre. This will set the aluminum and the rivet tight and flush. Being a useful tool it is now widely used in construction projects transportation industries aerospace manufacturing and many others.

The rivet can no longer be pulled through the hole because it is now flared on the underside of the. Before being installed a rivet consists of a smooth cylindrical shaft with a head on one end. Whether they are blindpop rivets singledouble capped tubular or solid copperbrass rivets that require a burr to secure them Rivets all work by squeezing layers of material together.

Insert Anchor Rivet into hole and squeeze handle. Insert your rivet into your pre-drilled hole. Pop rivets consist of two parts.

These are the basic parts of the rivet and they are easy to recognize. In situations where access to both sides of a component is limited a hole is first drilled through the parts to be joined. The blind rivet gets inserted into the riveting gun via the mandrel.

The end opposite to the head is called the tail. The nub end of the rivet will be pointing away from the gun. The pop rivet is passed through both holes in the sheet plastic aluminium.

A rivet is a permanent mechanical fastener. As the lower-scissor is held in place against the stop-plate at the bottom by the lower-return-spring when the raise-scissor gets pulled back by a raise-rod the top of the lower-scissor gets pulled back with it as it turns on the hinge-point small circle in the middle on that figure and thereby pushes the finger back for a raise. Then both ends are formed over the connection joining the parts securely.

Slide the rivet through the two holes. The rivet is set by drawing the stem through the shell which causes the shell to deform and clamp the material securely. The metal workpiece used to form the connection may be hollow or it may be solid.

A pneumatic rivet gun is very popular for its use in bonding metallic pieces. This will rivet the two surfaces together by driving the pin into the rivet. We know now the rivet parts like rivet head rivet pin and the rivet end.

Figure 9 - Riveting Seams. The rivet pliers are pushed on to the pin of the rivet and the handles are pulled together. The rivet is deformed by pounding or smashing of the tail which makes the material flatter and usually causes the tail to be expanded by about one and a half times the size of the stems original diameter.

Blind rivets are a two-part fastener consisting of a shell and a headed stem mandrel assembled so the shell can be placed into the work to be fastened. Typical All-Pull raise example. To Install Anchor Rivets 6-32x1-14 or 6-32x2-38.

When using the closed rivets on the product it is also important to use appropriate tools and equipment. This draws all of the parts tightly together and makes the rivet tight in. Insert it into the riveting tool.

After the desired clamping force is achieved. Move rivet tool down against flange of rivet so that nosepiece is again. A rivet is a visible part of the product.

This Design Squad Nation animation shows how a pop rivet clamps two pieces of material together. Install a rivet in the skin place the dimple set block on the back side and lightly drive the rivet into the dimple set block. The rivet acts to join the parts through adjacent surfaces.

When installed the rivet is either drilled placed or punched into a hole afterwards the tail is then deformed holding the rivet in place. This will expand Anchor Rivet in hole. Coming to the riveting it is the forging process that may be used power for fixing the parts together by engrossing and facilitating the use of metal part known as the rivet.

Obverse and reverse side. Identify the long pin of the rivet. Rivets have many uses such as in the construction and sheet metal industries.

14Thread proper Anchor Mandrel 25 or 26 onto Nut Anchor Case 20. 23Drill proper sized hole for Anchor Rivet to be used.

How Does A Blind Rivet Work Wonkee Donkee Tools

Illustration Of The Friction Stir Blind Riveting Process A The Download Scientific Diagram

Usually Rivets From 3 16 Diameter Through 1 2 Are Easy To Obtain In Commonly Useful Lengths Custom Rivets Blacksmithing Sheet Metal Tools Blacksmith Tools

Figure 3 4 Installing Blind Rivets Blinds Rivets Handy Woman

Pin On Bags Handbag Patterns Ideas For Bagmaking

What Is A Rivet How Is Riveting Done Riveting Definition Types Of Rivet